- Reale

- china

- 10-30days

REALE UV aging test chamber is designed by the Huanrui engineers through drawings, and then manufactured by Huanrui production department according to strict production processes. After repeated debugging before shipment, to ensure that each UV aging test chamber can normally meet customer needs.

UV Aging Test Chamber

UV Aging Test Chamber equip with ultraviolet lamps to simulate the radiant effects of sunlight, and simulates dew and rain through condensation and water spraying. In just a few days or weeks, UV irradiation equipment can reproduce the outdoor needs of months or years Damage that occurs over time, including discoloration, color change, dullness, chalking, cracking, cracking, wrinkling, blistering, embrittlement, reduced strength, oxidation, etc.

Feature of REALE UV Aging Test Chamber

Equipped with 8 UVA-340 (315 ~ 400nm) lamps

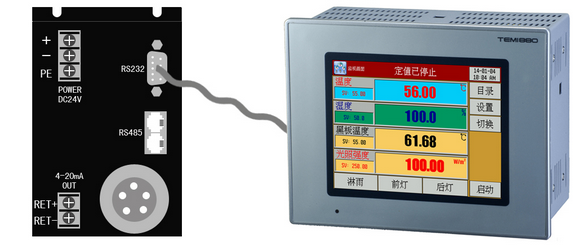

Temperature control method: PID self-tuning temperature control method

Real-time recording of irradiance, temperature and time

Can generate reports and curve print test data after connecting to a computer

Irradiation / condensation / water spray test can be tested individually or in combination

Meet the standards

ASTM D4587-2005, Standard Practice for Fluorescent UV-Condensation Exposures of Paint and Related Coatings

ASTM D5208-2001, Standard Practice for Fluorescent Ultraviolet (UV) Exposure of Photodegradable Plastics

ASTM D4799: Standard Practice for Accelerated Weathering Test Conditions and Procedures for Bituminous Materials (Fluorescent UV, Water Spray, and Condensation Method)

ISO 4892-3: Plastics - Methods of Exposure to Laboratory Light Sources - Part 3: Fluorescent UV Lamps

ISO 48-3-2006, Plastics - Methods of exposure to laboratory light sources - Part 3: Fluorescent UV lamps

ISO 4892-1: Plastics - Methods of Exposure to Laboratory Light Sources - Part 1: General guidance

Reference model

Model | RUV-1 | RUV-2 |

System | Balanced temperature and humidity control system | |

Temp. range | RT~70℃ | |

Humidity range | 20~98%R.H | |

UV wavelength | 280~400nm | |

Distance from sample to lamp | 50±2mm | |

Centre distance between lamps | 70mm | |

Peak energy | 0.8~0.9W/m2 | |

Way of exposure | Steam condensation exposure, radiation exposure | |

Controller | Japan original temperature controller, imported programmable time controller | |

Internal dimension(cm) | 1140X390X400cm | 1100X600X400cm |